What Does Aws Cwi Do?

Table of ContentsThe smart Trick of Aws Cwi That Nobody is DiscussingSome Ideas on Aws Cwi You Need To KnowThe smart Trick of Aws Cwi That Nobody is Talking AboutAws Cwi for DummiesThe 9-Minute Rule for Aws Cwi

Have you ever considered an occupation as a welding assessor? A welding examination accreditation is not just a fantastic achievement, it validates your capacities in the welding sector.

Coming To Be a Qualified Welding Inspector reveals your commitment to expanding within the welding market. This certification is one that should not and will certainly not be forgotten! As a CWI, you'll have the ability to make use of a number of various opportunities amongst industry professionals.

As you may know, welding is one of the most complex solutions within the steel fabrication market (https://www.wattpad.com/user/awscw1w3lding). The end result of every welding task is highly reliant upon individual welder skill.

The Only Guide to Aws Cwi

There's no uncertainty that CWIs help to copyright higher levels of consistency and top quality to the welding divisions they look after. This article gives a quick overview of the main benefits of collaborating with a metal fabrication business that employs certified weld examiners. It's not unusual that a lot of top-level industries will require you to work with certified welding inspectors to look after welding.

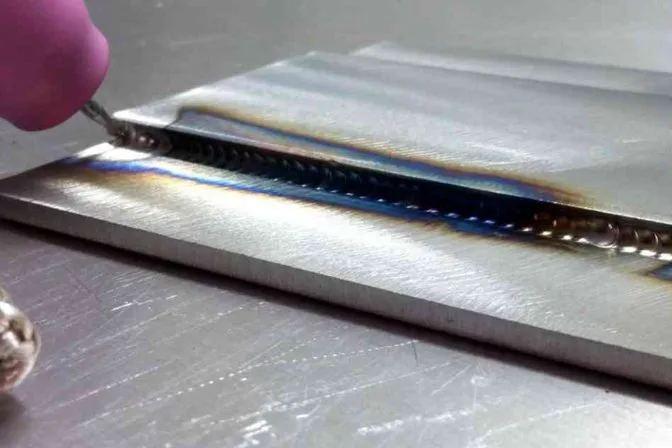

Qualified welding assessors have years of experience and hence, they comprehend the subtleties of conformity with welding codes. Complying with the welding process, CWIs can perform a series of test to examine the high quality of a weld, consisting of aesthetic assessment, heat therapy and a hydrostatic examination. Welding Inspection Agency. They can likewise make the correct modifications to the pre-weld prep work and the in-weld procedures as necessary

An in-house licensed welding assessor will certainly have the ability to assure that your task is tailored to all the needs of appropriate welding codes, ensuring its top quality. Welding assessors can assess welding procedure requirements, building and welding plans, devices calibration and welding materials. A welding examiners capability to offer welding treatment specs uses the steel construction company a substantial side of the competition, allowing makers to design welds that finest fit specific components, rather than utilizing tried-and-true welds.

The Single Strategy To Use For Aws Cwi

As previously stated, a CWI is not just liable fore creating the treatments for the weld, but likewise the quality-check screening procedures. https://www.40billion.com/profile/999225773. Beyond that, welding inspectors function to guarantee that equipment is effectively prepped for the work which welders are able to finish their welds with competence (Certified Welding Inspector). A qualified welding inspector will have had several years of experience, which a steel manufacture company can utilize to make sure stellar end results for all construction jobs that entail welding

This is why it's crucial to locate a welding company with a knowledgeable and highly educated in-house qualified welding assessor on staff. CAMM steels is such a company, so contact us today if you have a future job that needs quality custom-made welding! It's clear that a custom metal fabrication supplier with internal CWIs has devoted to investing in the quality of its welds.

Some industries require CWIs to be involved in the manufacturing of components. In the long run, CWIs think quite a little bit of obligation, yet their experience shows in the end product. Right Here at CAMM Metals, after the welding section of the job is complete, we offer numerous internal solutions. These solutions include weld assessment with dye penetrant, acid cleansing and sprucing up of stainless-steel welds.

For those customers who call for certified welds, we can license our welds to AWS D1.1 & AWS D1.6.

Aws Cwi Can Be Fun For Everyone

It's vital to note that many companies do not constantly require welders to be licensed. The main distinction is that licensed welders have actually composed records of their examination results and their efficiency is constantly monitored with routine assessment( s) being part of the efficiency document for each welder.

Before taking the test all PFS welders are educated, if called for, in the real welding procedure that they will certainly be utilizing and they will certainly require to have a functioning expertise of the welding tools, welding palatable and the material to be welded. description Effectively passing one test will certainly enable the welder to deal with numerous kinds of fabrications Will certainly not permit him to function on all types of construction as there are qualification ranges enforced for each test configuration.

Crucial variables include but are not restricted to product kind, palatable kind, material thickness and welding position. etc. After the welder has finished his test plate or pipe the weld is inspected making use of the complying with NDE procedures: Aesthetic Assessment X-Ray Liquid Penetrant Screening In some cases, the weld is also destructively examined.

The Aws Cwi PDFs

PFS completes this utilizing a continuity record that details all welds that a welder makes. If a welder does not use the welding process in a 6-month period, after that they will be requalified because procedure. The benefits to making use of a qualification system are several but the major advantages are: It validates the skill of a private to do based on a qualified welding treatment requirements (WPS) to create a great weld.